Manufactured as per API 11B with strict dimensional control and heat treatment, ensuring predictable field performance

Manufactured as per API 11B with strict dimensional control and heat treatment.

Available in multiple grades and sizes for different depths, loading conditions and environments.

Designed for durability, strength and predictable performance under cyclic loads.

Straightened, forged, marked, heat treated, shot blasted and inspected using magnetic particle testing.

End-head straightened, threaded, painted and packed in-house for consistent quality and traceability.

| Grade | Chemistry | Yield min ksi (Mpa) |

Tensile min ksi (Mpa) |

Tensile max ksi (Mpa) |

Elongation min % |

ROA min % |

Internal Color |

|---|---|---|---|---|---|---|---|

| C | Carbon (UNS G10XX0/G15XX0 or equivalent) | 60 (414) | 90 (621) | 115 (793) | 13 | 40 | White |

| K | Alloy (UNS G43XX0/G46XX0 or equivalent) | 60 (414) | 90 (621) | 115 (793) | 13 | 40 | Blue |

| DC | Carbon (UNS G10XX0/G15XX0 or equivalent) | 85 (586) | 115 (793) | 140 (965) | 10 | 40 | Brown |

| DA | Alloy (UNS G41XX0 or equivalent) | 85 (586) | 115 (793) | 140 (965) | 10 | 40 | Yellow |

| DS | Special (Ni+Cr+Mo ≥ 1.15% alloy content) | 85 (586) | 115 (793) | 140 (965) | 10 | 40 | Orange |

| HA (Alloy) | Alloy (UNS G41XX0 or equivalent) | 115 (793) | 140 (965) | 155 (1069) | 8 | 30 | Green |

| HA (Special) | Special (Ni+Cr+Mo ≥ 1.15% alloy content) | 115 (793) | 140 (965) | 155 (1069) | 10 | 40 | Purple |

| HY (Case hardened) | Case hardened (UNS G41XX0 or equivalent) | - | 155 (1069) ref. | - | - | - | Pink |

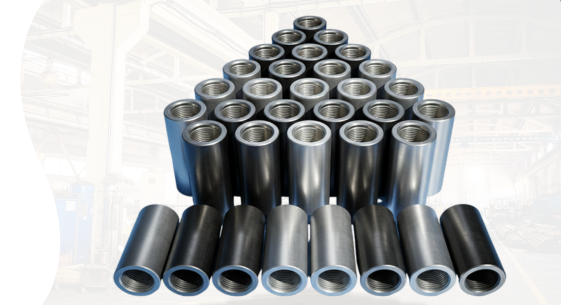

Manufactured in compliance with API 11B requirements.

Available in all sizes compliant with API 11B standards.

Precision machined for thread integrity, torque transfer and long service life.

Cut, drilled, threaded, phosphate and spray metal coated treated for anti-galling marked and packed entirely in-house for consistent quality and traceability.

| Grade | Chemical Composition | Yield min ksi (Mpa) |

Tensile Min ksi (Mpa) |

Tensile Max ksi (Mpa) |

Spray Metal Coating | Product Marking |

|---|---|---|---|---|---|---|

| TC Carbon | UNS G10XX0 or G15XX0 Series Steel | 60 (414) | 95 (655) | 125 (862) |

No

Yes

|

TC

TCS

|

| TA Alloy | UNS G41XX0, G51XX0 or G86XX0 Series Steel | 60 (414) | 95 (655) | 125 (862) |

No

Yes

|

TA

TAS

|

| TS Special | Any chemical composition containing Ni, Cr, Mo combination totaling min 1.15% alloying content | 60 (414) | 95 (655) | 125 (862) |

No

Yes

|

TS

TSS

|

| HA Alloy | UNS G41XX0, G51XX0 or G86XX0 Series Steel | 80 (552) | 125 (862) | 155 (1068) |

No

Yes

|

HA

HAS

|

| HS Special | Any chemical composition containing Ni, Cr, Mo combination totaling min 1.15% alloying content | 80 (552) | 125 (862) | 155 (1068) |

No

Yes

|

HS

HSS

|

Contact our technical team to discuss your specific requirements

Contact Us